New product – duct smoke sensor

1.6.2021

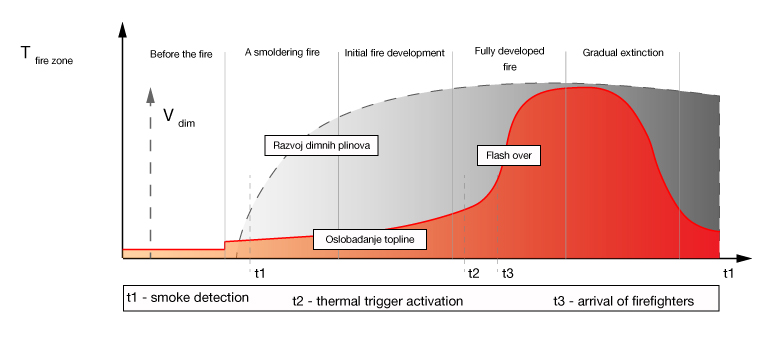

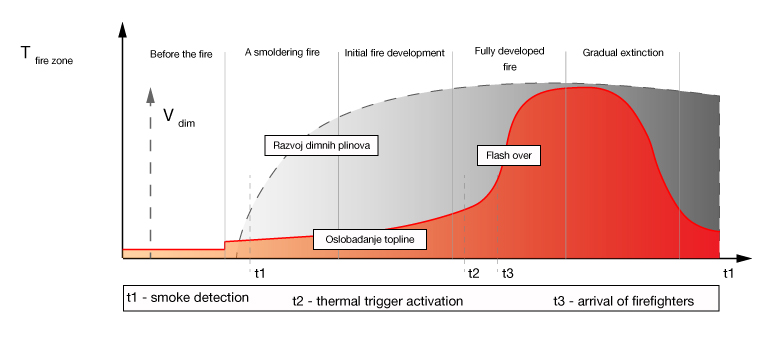

The general objective of fire protection measures in ventilation systems is to prevent the spread of fire and smoke, as well as to provide sufficient time for the safe evacuation of the premises. The installation of fire dampers is only a part of the measures related to the overall technical installations for fire protection in the ventilation system. In many cases, additional measures are needed to prevent the spread of fire and smoke between fire zones. The ventilation system is considered a serious safety problem as, by the very nature of the system, ventilation ducts connect the rooms in different fire zones more or less openly, thus allowing the passage of smoke. According to statistics, more than 90% of human fire victims are not the victims of fire itself, but of smoke poisoning or inhalation. Therefore, one of the basic requirements is to detect fire at an early stage, and this is most often achieved by smoke detection.

Figure 1. Stages of fire development

For several years now, active flue systems have been increasingly present in projects within the European Union. Active flue systems are designed to detect the location of a fire and ensure an appropriate response of the flue system and the ventilation system through predefined scenarios. The tasks of an active flue system are the following:

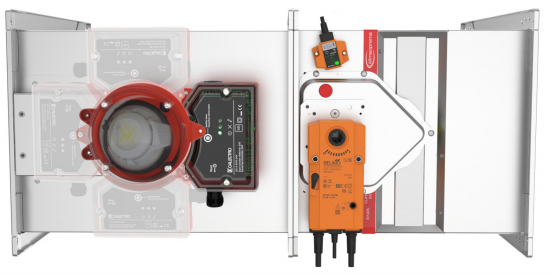

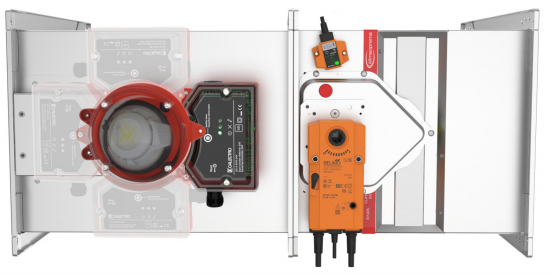

Figure 1. Duct smoke sensor

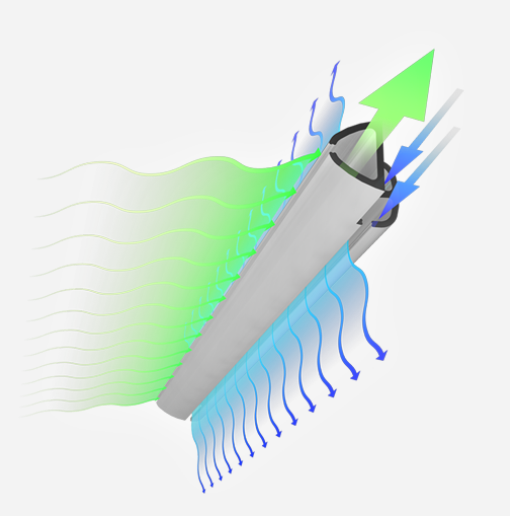

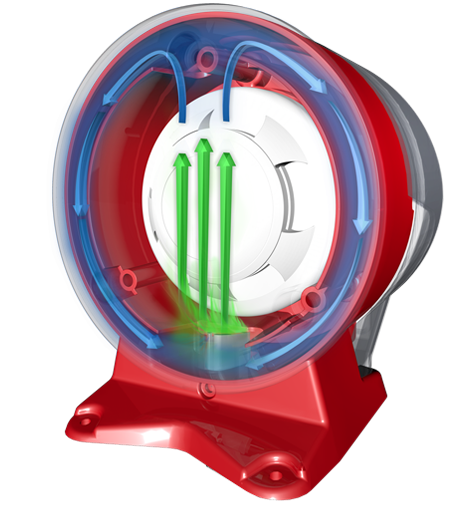

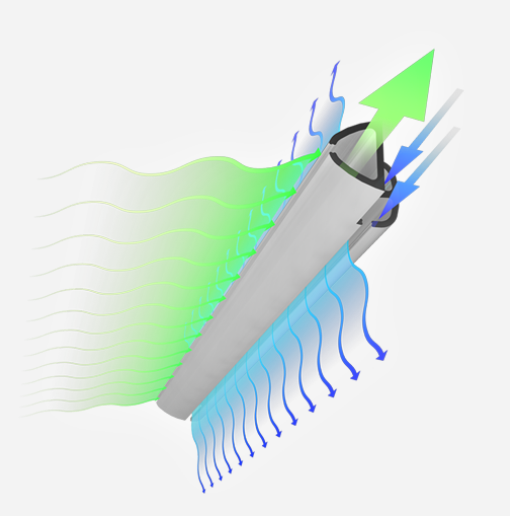

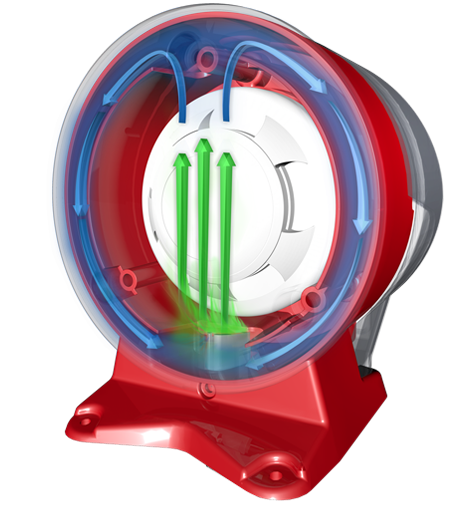

The SSA is most commonly supplied along with a fire damper to signal the presence of smoke in that fire zone. The advantage of joint installation is the wiring and cabling of the fire damper drive that connects directly to the smoke sensor, which is linked to a common power supply and able to communicate with other systems (fire alarms, flue system, CNUS). The duct smoke sensor consists of a housing, a sampling probe and a smoke sensor. The geometry of the probe affects the generation of a pressure difference between the front “stop” chamber through which the air enters the sensor and the rear “static” chambers through which the air returns back to the duct. The advanced design of the probe (Figure 2) and the smoke sensor (Figure 3) provides an efficient way of air circulation through the sensor and enables the measurement and detection of smoke particles in small doses and at low air velocities in the duct.

If smoke is detected, the sensor automatically closes the fire damper to which it is connected and sends a signal to the flue system, which triggers the fumigation of the area affected by the fire.

Figure 2. Sampling probe

Figure 3. Smoke sensor

By developing such systems, Klimaoprema further improves the functionality of its standard products that are part of the fire protection range, making them more competitive in the market which is growing every day.

Figure 1. Stages of fire development

For several years now, active flue systems have been increasingly present in projects within the European Union. Active flue systems are designed to detect the location of a fire and ensure an appropriate response of the flue system and the ventilation system through predefined scenarios. The tasks of an active flue system are the following:

- early smoke detection

- fire localization

- use of fire-fighting measures

- smoke extraction

- providing fresh air on evacuation routes

- achieving “overpressure” in adjacent rooms with the aim of preventing the spread of fire

- warning and alerting the competent services

Figure 1. Duct smoke sensor

The SSA is most commonly supplied along with a fire damper to signal the presence of smoke in that fire zone. The advantage of joint installation is the wiring and cabling of the fire damper drive that connects directly to the smoke sensor, which is linked to a common power supply and able to communicate with other systems (fire alarms, flue system, CNUS). The duct smoke sensor consists of a housing, a sampling probe and a smoke sensor. The geometry of the probe affects the generation of a pressure difference between the front “stop” chamber through which the air enters the sensor and the rear “static” chambers through which the air returns back to the duct. The advanced design of the probe (Figure 2) and the smoke sensor (Figure 3) provides an efficient way of air circulation through the sensor and enables the measurement and detection of smoke particles in small doses and at low air velocities in the duct.

If smoke is detected, the sensor automatically closes the fire damper to which it is connected and sends a signal to the flue system, which triggers the fumigation of the area affected by the fire.

Figure 2. Sampling probe

Figure 3. Smoke sensor

By developing such systems, Klimaoprema further improves the functionality of its standard products that are part of the fire protection range, making them more competitive in the market which is growing every day.